I was raised in a small village of less than 10,000 people in Norway. My family was filled with idealists and activists for both human and environmental causes. I vividly remember my dad in his office writing thousands of letters on behalf of Amnesty International on his typewriter to impact injustice in the World. The path I initially chose as a technologist and business entrepreneur was not necessarily the expected one.

In 2016, I was fortunate to sell Tapad, a company I founded, as one of the largest venture-backed exits in NY. After the sale, I wanted to take some significant time off and spend it with my wife and kids, then 4 & 8. So for 14 months we traveled – to over 30 countries. Truly the trip of a lifetime. But during our travels, I witnessed scenes that provoked questioning, certainly influenced by my upbringing, related to the staggering imbalance of the food system.

A staggering problem. The paradox of waste, hunger and the high tax we put on the Earth’s resources

We often read and hear about stories of global food insecurity. But it’s staggering to see thousands of starving people living in poverty close up. And, through the eyes of my young children. But during our travels we also saw vast amounts of crops left rotting in the field and food that went bad or was thrown out before it even reached a human.

When we returned to the States with an emotional connection to food disparity, I began meeting with my serial technology partner Dag Liodden, also from a socially involved family, to look at the hard facts:

- Nearly 1 billion people in the world do not have enough food to live a healthy life

- Each year, 1.6 billion tons of food worth about $1.2 trillion are lost or go to waste

- 20% of US landfills are comprised of rotting food

- Reduction of food waste is identified by the UN as the #1 priority to impact climate change

The problem was much bigger than I had initially thought.

The cause of the problem is slow-moving, inaccurate data

We needed to understand the root cause of the waste. Dag and I learned that a lot of the loss throughout the food chain can be attributed to a supply chain theory known as the ‘bullwhip effect’. The bullwhip effect theorizes that if information is not accurate or up to date when it’s sent through a supply chain, then a change of ± 5% in actual consumer demand can result in companies further back in the chain thinking it’s ±40%.

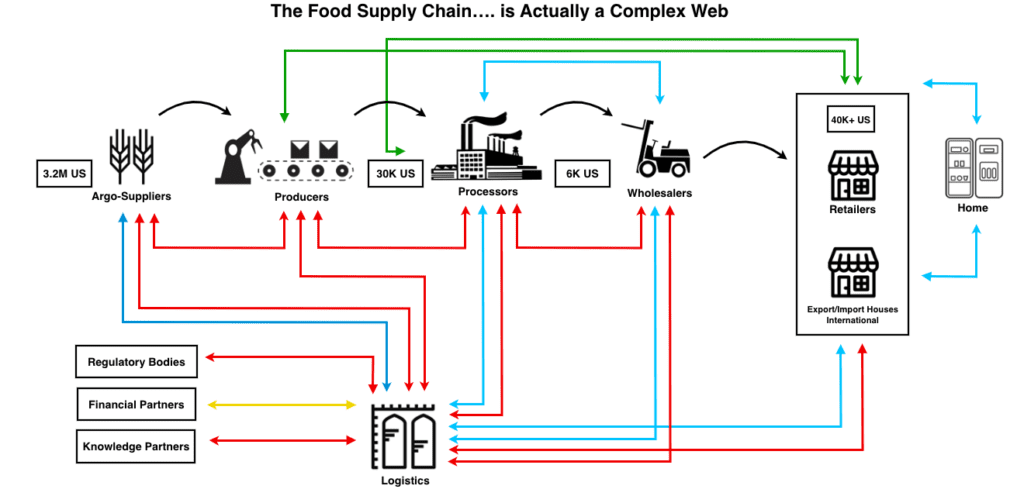

Now imagine a web of hundreds of thousands of companies all interconnected with each other with large ripples going through the system driven by weather, pricing, production, logistics, consumer shifts and you have… yes 1/3 of all food produced is lost before it reaches a human. These large ripples are at the core of food waste and are caused by each node in the network self-optimizing based on its own silo’d data and not on a universal set of accurate information. We concluded that, although a formidable challenge, we do bring tools to the table.

So how can we sustainably feed the population of the World?

As technologists at heart, we started looking at how the food supply industry operates today. The orange juice you drink at breakfast has likely had more than 10 stops in the supply chain before it is consumed (the fruit is grown at a farm, there can be a co-op representing a group of farmers, there is an exporter, a governmental body involved, an importer, a processor, several transporters, storage facilities, a brand, a wholesaler, a distribution center and finally a grocery store). If each of those say 10 companies have 5 IT systems, then your orange juice has “touched” 50 IT systems on its journey to your glass. Data is siloed in all of those IT systems. If the solution to the problem is real-time, accurate and reliable data, it is hard to achieve that with the current infrastructure of the industry, which is hampered by older, larger, expensive and inflexible ERP systems. And that is the real root of the problem.

At our last company together, we were able to connect and analyze trillions of signals from disparate sources and use computing power to make the data actionable. The food supply chain is ripe for a true data driven solution that gives a real time universal point of the truth. Dag and I have personally invested an initial $12M to allow Crisp to focus on building world-class technology and products the right way. We are committed to making product priorities based on our long-term goals, not short-term revenue. We are joined by an amazing team from technology, security, retail and the food industry to solve this problem.

And we are extremely grateful that FirstMark, partners from Tapad, have also already invested in Crisp as they identify with our mission and believe in our capabilities. When our friends at Swell Capital joined our mission too we had some of the old band back together — addressing a significantly larger and even more difficult industry but at the core of the solution are many of the same principles that we always have believed in. Gather data from tons of sources, organize huge amounts of data and then make data actionable to make a big difference.

Launching Crisp with a Double Bottom Line Goal

So, here’s where we are: Dag and I challenged ourselves to translate a “non-profit” goal into a commercially viable product that drives value for our customers and for Crisp. Food is likely the largest market in the world estimated at $8 Trillion so there is clearly a business opportunity as well. We are strong believers that sustained change can only happen if there is also a financial benefit for our customers. And there is. Lost sales because of out-of-stock situations or waste due to over-stock means lost profit. If our customers succeed, they drive more profits for themselves, revenue for us — and together we also contribute to solving one of the World’s biggest problems. We call it achieving a positive double bottom line.

A network of strong Crisp partners drives our product forward

We also understood that we had a lot to learn about the real pain points for suppliers and retailers. We spent months speaking to hundreds of experts and businesses in the industry, many of whom were incredibly gracious with their time and insights. It became clear that radical change needs to take place in order to create a sustainable food future.

Partnering almost from the start with REMA, an $8B in revenue grocery chain in Scandinavia, enabled us to understand the retail and food supply chain from behind the scenes. With access to real-time point of sale data, tracking and holistic tracing of inventory and delivery of more precise forecasts we are nearing a full view of the entire supply chain.

Our select group of over 25 Alpha customers in the US and Scandinavia, representing produce, seafood and meat suppliers, have enabled us to build a forecasting platform that will be the basis of a robust product suite. The product we have built requires minimal effort for customers to get started and provides value immediately to both growth brands and enterprise suppliers. Disruption via a product that is cloud based, set up in 10 minutes, and offers a free tier.

Coming full circle from my upbringing in Norway, I couldn’t be more excited and proud about our launch and what our Crisp technology can offer the world.